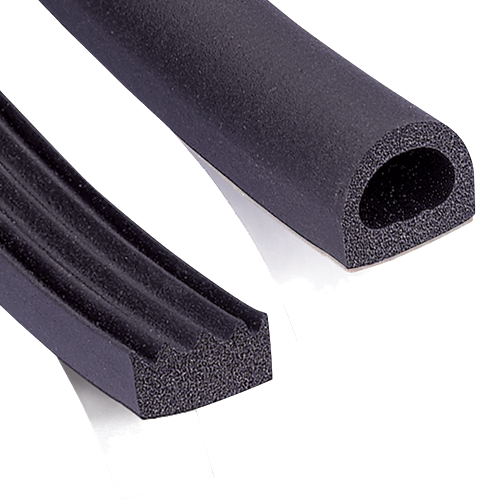

MOLDED & EXTRUDED

Many applications require a certain level of customization that is not easily achievable through standard straight cut fabrication techniques. In these specific circumstances, custom molded and extruded products can effectively provide a practical solution to the problem at hand. Molded rubber products encompass a wide variety of forms, including those produced using compression and transfer molds. These molded products can be crafted into various types such as homogenous designs, fabric-reinforced constructions, or rubber-to-metal composite products. In contrast, an extrusion differs from a molded rubber product in that the uncured rubber material is pushed through a specially designed die that is created to form the desired cross-sectional shape under high pressure. Following this shaping process, the extruded product undergoes vulcanization, or curing, in a heated pressure vessel that is referred to as an autoclave. Contact us today for more information!